Kings Quay FPS

Kings Quay FPS Project Summary: Oil Separation Train and Gas Compressor Scrubber Vessels Key Facts: Internals design and supply for (10) production train vessels and (5) BGC scrubber vessels. Scope: EPC-Process Design and Supply of Process Internals for the production vessels and gas scrubbers. Client: Major Independent Producer Challenge: Limited flexibility in the FPS footprint […]

Food and Beverage Process Optimization

Food and Beverage Process Optimization Project Summary: Process optimization for multiple food and beverage processing units to minimize foam generation and carry-under that was causing adverse process effects. Client: Major Beverage Company Challenge: Production processes at a food and beverage facility caused large amounts of foam, gas blow-by and higher liquid flow rates – which […]

Milne Point Alaska

Milne Point Alaska Project Summary: Provide process design and process internals for the slug catcher and water surge drum. Key Facts: Retrofitting was completed without requiring hot work All parts were installed by VME personnel Client: Major Alaskan Operator Challenge: Excess water/oil carry-over in the slug catcher and surge drum – needed to be converted […]

ENI Mexico Area 1 FPSO Project

ENI Mexico Area 1 FPSO Project Project Summary: EPC of the pressure vessels and process internals. Key Facts: Required the use of 4 Production Vessels and 2 Electrostatic Dehydrator/Desalters Client: International FPSO Provider Challenge: Project required 825 cladded vessels and local content for pressure vessel fabrication. VME Solution: Pressure vessel fabrication and internal installation was […]

Delta House FPS

Delta House FPS Project Summary: Provide retrofit internals for the test and HP Production Separator Trains, as well as provide new build VRU and Multi-Cyclone Filter Separator Pressure Vessels and internals. Key Facts: Retrofitting of existing vessels was completed with no hot work required. Operations noted that there has been a reduction in chemical dosing […]

Facility Program Orders – Major WTX Producer

Facility Program Orders – Major WTX Producer Project Summary: Supply client in the Permian Basin with Center Tank Battery (CTB) and Instrument Air Modules. Key Facts: Robust planning, MRP, and Quality Systems Manufacturing and construction standards that meet industry codes and client specifications Service – installation and start up of instrument air (Cortex) Client: Major […]

Three Phase Separator Program

Three Phase Separator Program Project Summary: Supplied 100 Three-Phase Heated Separator Packages for a client in the Permian and D.J Basin. Key Facts: 100 unit order Cold weather unit 48”-20’ heated three phase separator Target basin – DJ Client: Major Integrated Oil Company Challenge: The client needed more equipment in order to fulfill their annual […]

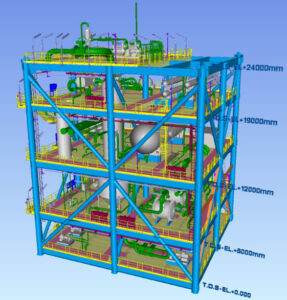

ENI – OCTP – GHANA

ENI – OCTP- GHANA Project Summary: Supply TCN-1 Topside Process Packages (6 modules, 2 skids) – including gas compression, gas dehydration and hydrocarbon dewpoint control, gas injection, oil treatment, crude stabilization, flare knockout and a Flare Gas Recovery Module. Key Facts: Associated Gas Flow 190 MMSCFD to 430 bara Non-Associated Gas (NAG) Flow 190 MMSCFD […]

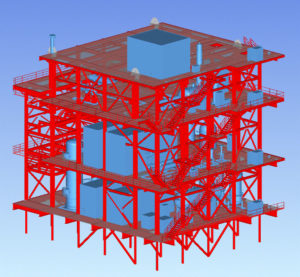

Baobab FPSO, Cote d’Ivoire, West Africa

Baobab FPSO, Cote d’Ivoire, West Africa Project Summary: HP, IP, LP Separators, Electrostatic Coalescer, Gas Processing Module Key Facts: Processing capacity of the Module – 75 MMSCFD Gas flow rate This project became the springboard for expansion of VME into Asia – particularly on the fabrication of Topsides Modules. VME First: EPC Scope for Offshore […]

Multi-Well Modules

Multi-Well Modules Project Summary: This is an ongoing (2015-2021) project in which VME has been hired to manufacture and deliver multiple prefabricated well site modules to the Permian and D.J. Basin. Key Facts: Customer partnership Coordination with construction contractors 50% reduction in time to first oil No weather delays during fabrication Higher quality product (controlled […]