VME Process Asia Pacific has been selected by a client to supply a Monoethylene glycol (MEG) regeneration and reclamation package (MRU) for a “platform based” offshore installation.

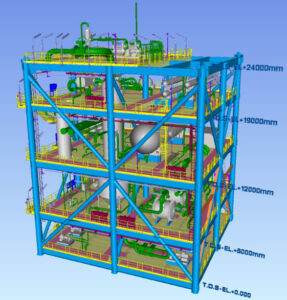

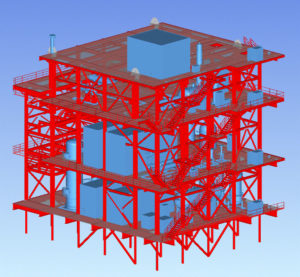

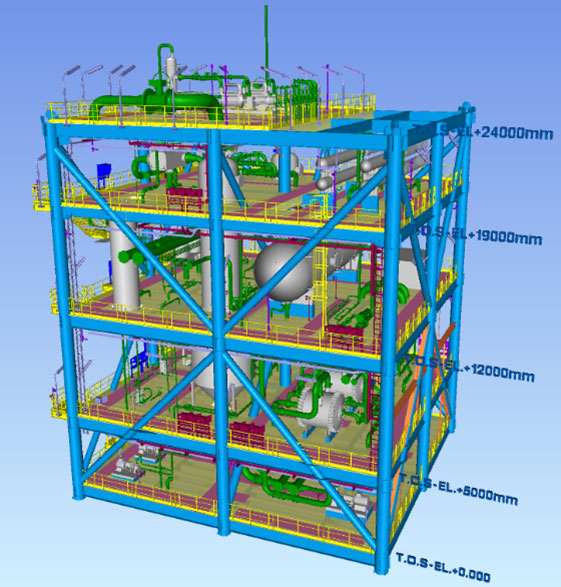

The project was awarded in July 2022 and will be executed out of our Malaysian offices on an 18-month EPC schedule. The module is 25m x 20m x 27m and weighs 1,250 tonnes.

VME’s MEG process consists of a common pre-treatment, produced water and salt handling systems as well as two trains of Integrated MEG reclamation and regeneration.

Rich MEG enters the process from the upstream rich MEG condensate treatment system. The pre-treatment system provides heat recovery and conservation while removing undesirable components from the rich MEG phase. The treated rich MEG is then vaporized and separated via distillation to produce a salt-free, lean MEG stream containing 90-wt% MEG. Solid salts from the residue that remains after vaporization are removed using centrifuges.

The process recovers >99.5% MEG recovery using VME’s fully automated glycol reclamation process.

“The project is progressing extremely well,” said Nurhaniza Zubir, VME Project Manager. “HAZOPs are completed, procurement is moving forward and the project safety performance is ZERO TRIR to date. I have a great team and look forward to seeing the unit commissioned early in 2024.”