June 13, 2017 (TYLER, TX) – Energy equipment company VME has recently been awarded contracts for multiple modularized wellsite facilities.

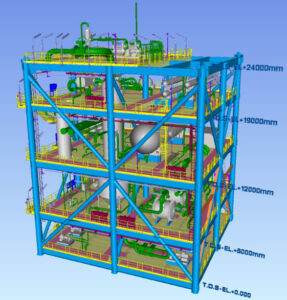

The company’s North Texas fabrication facility will provide full wellsite piping, pipe racks, separation, measurement, and fluid transfer systems for a multi-well pad drilling program.

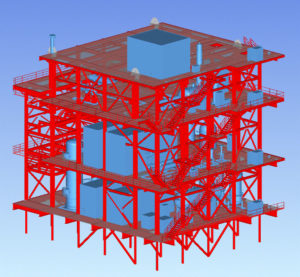

Compared to traditional wellsite construction methods, VME uses a streamlined manufacturing platform incorporating cost efficient one-piece flow with unique material management methods, efficient production techniques, and quality systems clients expect from a global process module fabricator.

Greg Jean, General Manager and Vice-President of Fabrication, said, “Our production methodology addresses several critical cost issues customers experience with traditional modularized equipment fabrication. A good example is the way we maximize skilled labor utilization by planning and staging our production work areas. This virtually eliminates the wasted cost of material handling and the delays experienced in traditional fabrication shops and allows us to pass on the lower cost of production to our clients.”

Michael Thomas, VME CEO, said, “We see customers with large drilling programs moving toward fabrication of modularized wellsites because they can reduce the cost of facilities by 30% and wellsite construction times by up to 70% over traditional field construction.”